|

| |

R2 Controls Completes major control projects at Sunoco

2nd major project improves yield

Jan2001 -- The recent project involves exothermic

reactors, reactor modeling, reactor analysis, and reactor instruments and

controls. This project comes on the heels of a previous reactor control

project that used a similar overall methodology. The reaction is basically

heat CHP (Cumene Hydroperoxide) with a little catalyst, and remove the heat as

fast as it is formed. The process is typical for a "Phenol Production

Plant" and the process technology is licensed for general use by UOP and

Sunoco. The overall process starts with Cumene reacting with oxygen to

form CHP. The CHP is decomposed to form the products Phenol, Acetone, and

AMS. This project involved the second reaction which is the decomposition

of CHP. A joint Invensys, Sunoco, and R2Controls paper is being

written on the most recent project and should be available soon.

The

decomposition reactor was modeled with detailed kinetics. The reactor was built

as a "User Block" in Aspen plus flowsheet simulator. The model was

very useful to compute what the reactor would make for any conceivable reactor

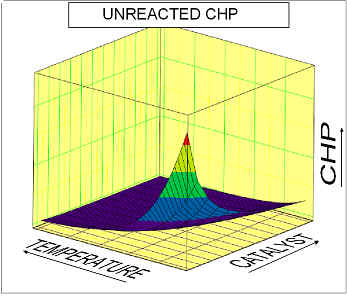

operating condition. If you notice the 2 graphs shown here, you can see

some calculations made from the reactor models, including the optimal operating

point. To verify the model, the reactor was tested with a DOE (Design of

Experiment) type of test. This is a hard thing to do on an operating unit,

but the results were worth the effort. Prior to running these tests,

certain instrument and regulatory control improvements were made. Test results

showed the models were not in complete agreement with the plant tests, but they

were close, and the overall conclusions and optimal operating points computed

with the models were confirmed. This information was essential to

structure the control system, as we needed to specify which constraints would be

involved, and what direction the control system needed to go to drive the

operation to the most profitable operating point. The control system was

implemented using DMC+ multivariable control technology. The controls were

relatively simple as multivariable controllers go, involving 3 MV's (Manipulated

Variables) and 5 CV's (Controlled Variables). A dynamic simulation using

Cape Software, www.capesoftware.com

was used for control system testing and for operator training. By starting

with a detailed understanding of the process, making required instrumentation

and regulatory control improvements and finally implementing a relatively simple

multivariable controller, the process has never been operated better and is

destined for optimal operation in the future. An audit comparing before

and after operation shows a significant increase of yield in the most valuable

AMS product and greatly improved stability as evidenced by standard deviations

of important controlled variables. The

decomposition reactor was modeled with detailed kinetics. The reactor was built

as a "User Block" in Aspen plus flowsheet simulator. The model was

very useful to compute what the reactor would make for any conceivable reactor

operating condition. If you notice the 2 graphs shown here, you can see

some calculations made from the reactor models, including the optimal operating

point. To verify the model, the reactor was tested with a DOE (Design of

Experiment) type of test. This is a hard thing to do on an operating unit,

but the results were worth the effort. Prior to running these tests,

certain instrument and regulatory control improvements were made. Test results

showed the models were not in complete agreement with the plant tests, but they

were close, and the overall conclusions and optimal operating points computed

with the models were confirmed. This information was essential to

structure the control system, as we needed to specify which constraints would be

involved, and what direction the control system needed to go to drive the

operation to the most profitable operating point. The control system was

implemented using DMC+ multivariable control technology. The controls were

relatively simple as multivariable controllers go, involving 3 MV's (Manipulated

Variables) and 5 CV's (Controlled Variables). A dynamic simulation using

Cape Software, www.capesoftware.com

was used for control system testing and for operator training. By starting

with a detailed understanding of the process, making required instrumentation

and regulatory control improvements and finally implementing a relatively simple

multivariable controller, the process has never been operated better and is

destined for optimal operation in the future. An audit comparing before

and after operation shows a significant increase of yield in the most valuable

AMS product and greatly improved stability as evidenced by standard deviations

of important controlled variables.

For More Information Contact:

www.sunocochem.com

or

R2 Controls

128 Mountain Road, Princeton, MA 01541

Tel: 508-369-5186 cell phone

FAX: None - Please use E-Mail

Internet: rys@R2Controls.com

|